Touch Display Module: Features, Uses, and Selection Guide for 2025

News

Jun-22-2025

Choosing the right display for your product or system isn't just about screen size—it's about function, durability, and user interaction. In 2025, touch display modules are becoming the go-to solution across industries, offering compact, integrated designs that simplify development and improve user experience.

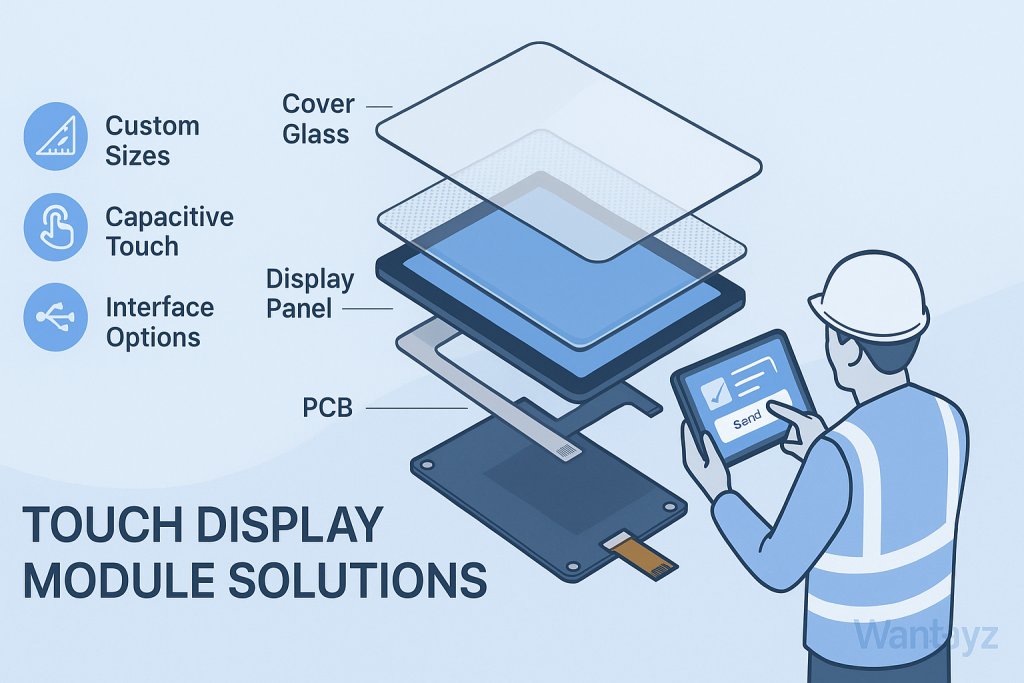

These modules combine a touch interface, display panel (usually LCD or TFT), and control board in one unit—saving space and cutting down on wiring. Whether you're designing a handheld medical device, a smart vending machine, or an industrial HMI, a well-chosen touch display module can reduce complexity and speed up your build.

From basic control panels to advanced multi-touch screens with built-in processors, these modules now support glove use, high brightness for outdoor readability, and responsive interfaces even in demanding environments.

In this guide, we’ll explain what makes up a touch display module, explore real-world use cases, and offer tips on how to choose the right one for your project in 2025.

Core Components of a Touch Display Module: Display + Touch + Controller

A touch display module is like a high-tech sandwich, combining three main parts. The display, often an LCD or OLED, shows images and data. The touch sensor, usually capacitive, detects your finger’s touch through an electrical field. The controller board processes these touches, turning them into actions like opening an app. For example, a retail kiosk uses a module to show a menu and respond to taps instantly. The controller board ensures touch accuracy, while the display provides optical clarity. Together, these components create a seamless user interface for devices like medical monitors or car dashboards. In 2025, HMI screen modules rely on these parts to deliver reliable, responsive performance across industries.

Touch Displays Used in Modules: TFT, OLED, LCD, IPS

Touch display modules use different display types to suit various needs. TFT (thin-film transistor) LCDs offer sharp images and are common in kiosks for their affordability. OLED displays provide vibrant colors and deep blacks, ideal for smartphones. Standard LCDs are budget-friendly but less vivid, used in simple devices. IPS (in-plane switching) LCDs deliver wide viewing angles, perfect for medical monitors where clarity matters. For example, a gym bike might use a TFT LCD touch panel to show workout stats clearly. Each type affects resolution and optical clarity, impacting the user interface. In 2025, choosing the right display type ensures your touchscreen module meets your project’s visual and performance needs.

Capacitive vs Resistive Touch in Display Modules

Most touch display modules use capacitive or resistive touch technology. Capacitive modules, like projected capacitive touchscreens, detect touches through an electrical field, offering multi-touch for swiping or zooming. They’re precise and clear but may need glove compatibility tuning. Resistive modules use pressure, working with any object but lacking multi-touch. For instance, a capacitive HMI screen module in a tablet lets you pinch to zoom, while a resistive module in an older ATM needs a firm press. Capacitive modules dominate for their touch accuracy and optical clarity. To learn more, see What is a capacitive touch screen. In 2025, capacitive touchscreen modules are preferred for modern user interfaces, while resistive suits budget or rugged uses.

Common Applications of Touch Display Modules

Touch display modules power devices across industries. In retail, they drive point-of-sale touchscreens for quick checkouts. Medical devices use HMI screen modules for precise patient monitoring. Automotive dashboards rely on modules for navigation and music controls. Industrial control panels use rugged designs for factory automation. For example, a warehouse tablet with an LCD touch panel helps workers scan barcodes. Smart home devices, like thermostats, use modules for intuitive controls. Gaming consoles benefit from multi-touch for immersive play. These capacitive touch screen use cases show the versatility of integrated touch displays. In 2025, modules enhance user experience in countless settings. Explore more at Capacitive touch screen use cases.

Touch Display Module for Embedded Systems and IoT Devices

Embedded systems and IoT devices rely heavily on touch display modules. These compact units integrate displays, touch sensors, and controllers into one package, perfect for smart devices. For example, a smart thermostat uses an HMI screen module to let users tap to adjust temperature. IoT devices, like connected vending machines, use modules for real-time inventory tracking. The controller board ensures touch accuracy, while interface options like I2C or SPI connect to embedded systems. Capacitive modules offer multi-touch for swiping through settings, enhancing user interface design. In 2025, integrated touch displays power IoT growth, making devices like home hubs or industrial sensors intuitive and efficient, with rugged designs for reliability.

User Interface Design Considerations for Touch Modules

A good user interface design is critical for touch display modules. Screens need clear, large buttons for easy tapping, like on a retail kiosk where users select payment options. High clarity displays ensure readability in bright or dim settings, such as a car dashboard in sunlight. Multi-touch allows gestures like zooming, making navigation intuitive. For example, a medical monitor’s LCD touch panel needs sharp visuals for patient data. Accessibility features, like high-contrast modes, help diverse users. The controller board must process touches quickly to avoid lag. In 2025, HMI screen modules prioritize simple, responsive user interfaces to enhance user experience, ensuring devices from smartphones to factory panels are easy to use.

Screen Sizes and Aspect Ratios Available in Touch Modules

Touch display modules come in various sizes and ratios to fit different devices. Small modules (3.5–7 inches, 16:9) suit smartwatches or medical handhelds. Medium modules (10–15 inches, 4:3 or 16:9) work for kiosks or tablets. Large modules (15–55 inches, 16:10) power touch tables or digital signage. For example, a 10-inch touchscreen module in a POS system offers clear visuals for transactions. Common ratios like 16:9 ensure optical clarity for widescreen displays. Resolution varies from 720p for small screens to 4K for large ones, impacting user interface design. In 2025, choosing the right size and ratio for integrated touch displays ensures touch accuracy and user experience for your project.

Mounting and Housing Options for Touch Display Integration

Mounting a touch display module requires careful planning for a secure fit. Surface mounts attach screens to flat surfaces, like a kiosk panel, using brackets. Flush mounts embed modules into devices for a sleek look, common in car dashboards. Embedded mounts secure modules in rugged designs, like industrial panels. For example, a factory control panel uses a flush-mounted HMI screen module for seamless user interface design. Proper mounting hardware ensures enclosure compatibility, preventing vibrations. Wiring must be secured for interface reliability. In 2025, touch screen installation solutions ensure durability and touch accuracy. For more, see Touch screen installation solutions. Choosing the right mounting enhances integrated touch display performance.

How to Choose the Right Touch Controller for Your Module

The controller board is the brain of a touch display module, processing touch inputs. Choose one based on interface needs, like USB for kiosks or I2C for embedded systems. For example, a medical device might use a Synaptics controller for high precision. Ensure multi-touch support for gestures like swiping, critical for tablets. Touch accuracy depends on the controller’s sensitivity settings, especially for glove compatibility. Check compatibility with TFT or OLED displays to avoid lag. For instance, a retail POS system needs a fast controller for quick taps. In 2025, selecting the right controller board ensures a responsive user interface for touchscreen modules, enhancing user experience across applications.

Interfaces and Connectivity: USB, I2C, SPI, HDMI

Touch display modules connect to devices through various interfaces. USB is plug-and-play, ideal for kiosks or POS systems. I2C suits compact embedded systems like smartwatches, using minimal pins. SPI is fast for industrial panels, ensuring touch accuracy. HDMI handles high-resolution video for large displays, like touch tables. For example, a car dashboard’s LCD touch panel might use USB for easy integration. The controller board must match the interface to avoid connectivity issues. In 2025, HMI screen modules rely on these interfaces for seamless data transfer, enhancing user interface design. Choosing the right interface ensures integrated touch displays work smoothly with your device’s software and hardware.

Sunlight Readable and Rugged Touch Display Options

Sunlight readable touch display modules use high-brightness displays and anti-glare coatings for optical clarity in bright conditions. For example, an outdoor kiosk’s HMI screen module stays clear in sunlight. Rugged designs resist dust, water, and impacts, ideal for industrial environments. PCAP modules with thick glass surfaces ensure durability, like in warehouse tablets. Waterproof coatings protect against spills, while glove compatibility suits cold environments. In 2025, rugged touchscreen modules with sunlight readable features enhance user experience in tough settings, from construction sites to retail. These options ensure touch accuracy and reliability, making integrated touch displays versatile for outdoor or industrial use.

When to Use a Custom Touch Display Module

Custom touch display modules are ideal when standard screens don’t fit. For example, a medical device might need a 12-inch LCD touch panel with glove compatibility for surgical use. Tailor screen dimensions, resolution, or features like waterproof coatings to match your project. A curved module for a car dashboard ensures seamless user interface design. Custom controller boards optimize touch accuracy for specific inputs. These custom touch panel services cost more but meet unique needs, enhancing user experience. In 2025, customized capacitive touchscreens are key for embedded systems. Explore options at Capacitive touch custom screen to design your perfect touchscreen module.

Choosing a Reliable Manufacturer for Touch Display Modules

Selecting a capacitive touch screen manufacturer for touch display modules requires care. Look for certifications like ISO 9001 or RoHS for quality touchscreens. Ensure experience in your industry, like retail or medical. Check for customization options, such as glove compatibility or sunlight readable displays. Suppliers like Elo or Zytronic offer 1–3-year warranties and 24/7 support. For example, a kiosk project might need a rugged design from Faytech. Test samples for touch accuracy and durability. In 2025, a reliable manufacturer ensures HMI screen modules meet your needs. For options, see Capacitive touch screen manufacturer. Choosing the right supplier guarantees user interface quality.

Touch Display Module Pricing: What Affects Cost?

Touch display module costs range from $20–$2,000. Screen dimensions impact pricing: small 7-inch modules cost $20–$150, while 21-inch ones hit $500–$1,000. Resolution (e.g., 4K) and TFT or OLED displays raise costs. Features like glove compatibility or waterproof coatings add $50–$500. MOQ affects unit prices: bulk orders lower costs. For example, a 15-inch kiosk module might cost $300 for 1,000 units. Tooling for custom orders adds $1,000–$5,000. Compare touchscreen price inquiries to balance cost and quality. For pricing tips, see Capacitive touch screen quote. In 2025, smart budgeting ensures integrated touch displays meet your project’s needs.

Testing and Quality Assurance in Display Modules

Testing touch display modules ensures reliability. Manufacturers check touch accuracy to confirm precise inputs, like tapping a POS screen. Durability tests verify the glass surface resists scratches or impacts. Resolution and optical clarity are tested for clear visuals, crucial for medical monitors. Environmental tests ensure rugged designs handle dust or water. For example, a warehouse tablet’s HMI screen module must work in dusty conditions. Certifications like ISO 9001 guarantee quality. In 2025, thorough testing ensures touchscreen modules deliver user experience and durability. Request test reports from capacitive touch screen suppliers to confirm controller board performance and interface reliability for your project.

Installation Challenges and Solutions

Touch screen installation solutions for touch display modules face challenges like misalignment or connectivity issues. For example, a kiosk module might misread taps if not calibrated properly. Secure mounting hardware prevents vibrations in industrial environments. Use shielded wiring for interface stability, like USB in retail POS systems. Ensure enclosure compatibility for seamless bezel integration. Calibrate multi-touch for touch accuracy, testing in real conditions like bright lighting. If issues arise, consult capacitive touch screen suppliers for support. In 2025, careful installation ensures integrated touch displays perform reliably, enhancing user interface design.

Real-World Case Studies Using Touch Display Modules

Touch display modules shine in real-world settings. Elo supplied 3,000 LCD touch panels for retail kiosks, ensuring multi-touch for fast ordering. Zytronic delivered 1,000 rugged HMI screen modules for factory panels, with glove compatibility. Faytech provided 2,000 touchscreen modules for medical monitors, offering high precision. Touch International equipped car dashboards with curved integrated touch displays for navigation. These capacitive touch screen use cases highlight durability and user experience. In 2025, touch display modules drive efficiency across industries, from retail to healthcare.

Future Trends in Touch Module Technology

In 2025, touch display modules are evolving fast. AI integration predicts user inputs, like suggesting workout settings on gym screens. Haptic feedback adds tactile responses for a button-like feel. Flexible TFT or OLED displays enable curved modules for wearables. Gesture input allows touchless controls, ideal for hygienic settings. Edge computing processes data locally, boosting touch accuracy in embedded systems. For example, a smart kiosk might use an AI-powered HMI screen module to streamline orders. These trends enhance user interface design and durability, making integrated touch displays key for IoT and consumer tech in 2025, driving innovation across industries.

Conclusion

Touch display modules are the heart of modern devices in 2025, from LCD touch panels in kiosks to HMI screen modules in factories. With multi-touch, touch accuracy, and rugged designs, they enhance user experience across retail, medical, and industrial applications. Choose screen dimensions, resolution, and interfaces like USB or I2C to match your project. Work with trusted capacitive touch screen suppliers like Elo or Zytronic for quality. Custom modules, like those at Capacitive touch custom screen, meet unique needs. Budget for unit prices and test for durability to ensure reliability. Ready to power your device? Contact a Capacitive touch screen manufacturer for the perfect touchscreen module.

Related Topics

Capacitive Touch Integrated Touchscreen: 2025 Technology

Aug-25-2025

Capacitive Touch Screen POS Terminal – Next-Gen Solutions

Aug-25-2025

Capacitive Touch HMI Interface | Durable & Ergonomic Control

Aug-24-2025

Capacitive Panel OEM Manufacturers – Custom Touchscreen Solutions

Aug-24-2025

Get a Free Quote

✔ 16 Years Manufacture Service ★★★★★

✔ 3 Technical Experts And 52+ Project Engineers Will Assiste You

✔ Wanty Employs Over 52 Engineers, Many Of Whom Come From Leading Tft Lcd Module Companies Such As Tianma And Boe-Varitronix. Each Core Team Member Brings 15 Years Of Industry Experience.

✔ If you would like more information about our products and services, please contact us. Whether you need a standard solution or a customized one, we are here to meet your needs.

✔ Please complete the form below, and the selected location will contact you promptly. Thank you for visiting, and have a great day!