Custom Tft Lcd Panels

Custom Touch Screen

Jun-24-2024

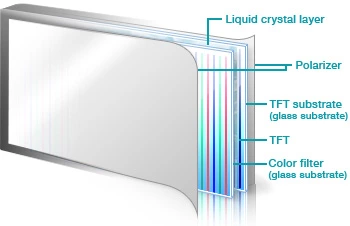

The TFT LCD panel is the central component of a liquid crystal display, consisting of two glass layers. The upper glass layer, known as the color filter (CF), is equipped with transparent electrodes. The middle layer contains the liquid crystal filling. The lower glass layer, called ITO glass, includes signal electrodes, alignment electrodes, and thin-film transistors on the substrate glass.

The production process of TFT LCD panels is quite complex, requiring any modifications to be made with great care.

Thinness:

You may require a thinner TFT LCD module due to design requirements or structural constraints. However, TFT modules need backlight modules and polarizers, which add to their thickness. After selecting the thinnest possible backlight and polarizer, if your requirements are still not met, we can thin the TFT LCD panel itself. For example, we can reduce a single glass layer from 0.5mm to 0.2-0.3mm. Since a TFT LCD panel consists of two glass layers with liquid crystal in between, we can thin an original 1.0mm LCD panel down to 0.4-0.6mm. This reduction significantly impacts the overall thickness, making it very valuable.

• Advantages: thinner and lighter

• Disadvantages: lower yield, higher cost

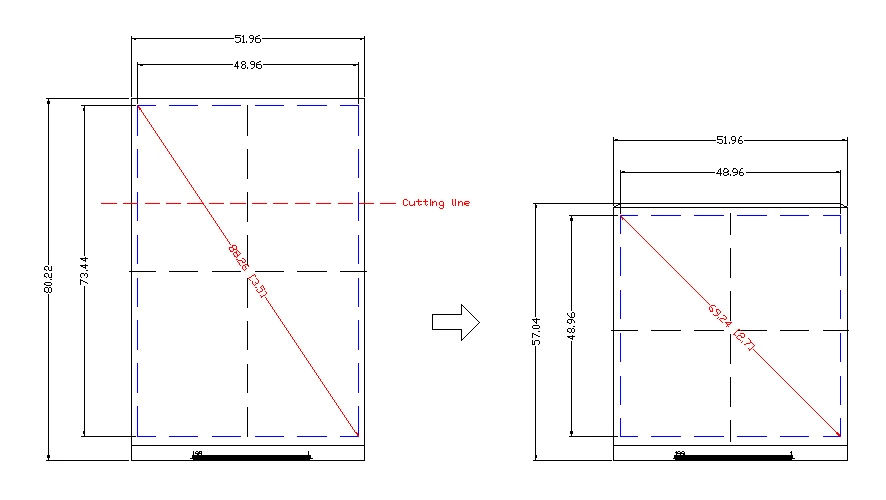

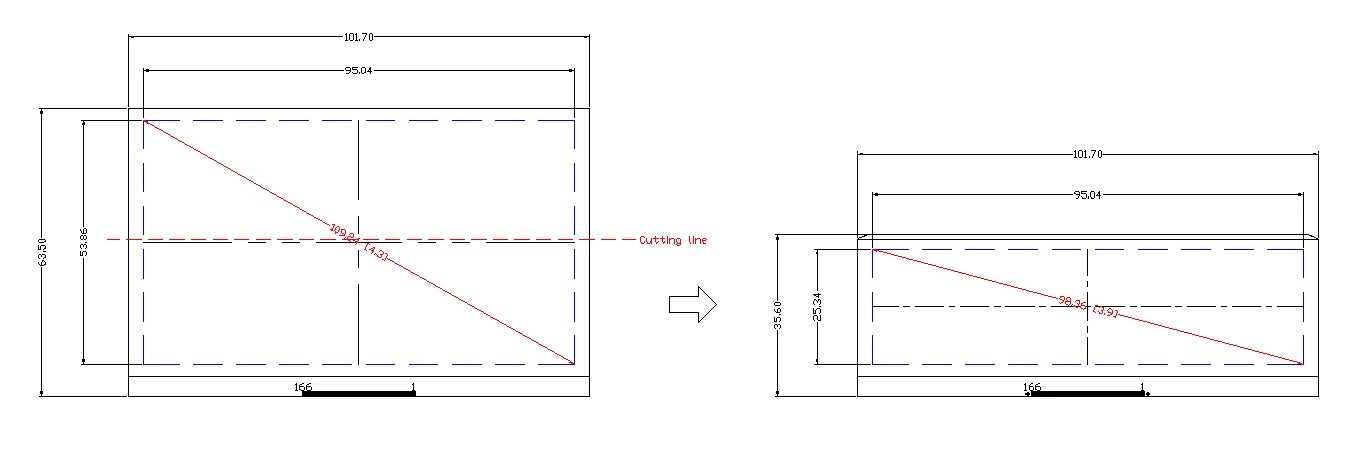

Cutting:

We can modify an off-the-shelf TFT LCD panel to change its original shape, such as converting a 16:9 screen to a 16:6 screen, a 4:3 screen to a 4:2 screen, or a 3:2 screen to a 1:1 square. However, not all LCD panels are suitable for cutting. The feasibility depends on the panel’s orientation and circuit design. Therefore, each solution requires careful evaluation and experimentation.

• Advantages of custom-cut TFT LCD panels include the ability to achieve special resolutions and sizes, making them ideal for creating square or elongated displays.

• Disadvantages include reduced yield, higher costs, limited suitability for all products, and the need to match the ITO orientation and driving method of the LCD panel.

3.5 inch ->2.7inch

4.3 inch -> 3.9 inch

Customize the TFT LCD panel:

Most TFT LCD panels come in fixed sizes and resolutions. However, if you need a custom size or special resolution not available on the market, we can assess your requirements and provide the right solution to make your product stand out. Customizing a brand new LCD screen involves significant tooling costs and requires large order quantities. If your order is small, this option may not be suitable. For larger orders, we will determine the most economical production line based on the size of the LCD panel. We will also consider tooling costs, minimum order quantities, and unit prices to provide the best solution for your needs.

• Advantages: A unique product and a period of product protection during which no one can use your customised panel.

• Disadvantages: High tooling costs and very high MOQ requirements.

Related Topics

Custom Capacitive Touch Screen

Jul-08-2024

Matching accessories

Jul-08-2024

LCD boards Add-Ons

Jul-08-2024

Low Cost All Viewing Solution

Jul-08-2024

Get a Free Quote

✔ 16 Years Manufacture Service ★★★★★

✔ 3 Technical Experts And 52+ Project Engineers Will Assiste You

✔ Wanty Employs Over 52 Engineers, Many Of Whom Come From Leading Tft Lcd Module Companies Such As Tianma And Boe-Varitronix. Each Core Team Member Brings 15 Years Of Industry Experience.

✔ If you would like more information about our products and services, please contact us. Whether you need a standard solution or a customized one, we are here to meet your needs.

✔ Please complete the form below, and the selected location will contact you promptly. Thank you for visiting, and have a great day!