Conductive Film Touch Panel: Flexible for Modern Interfaces

News

Aug-18-2025

What is a Conductive Film Touch Panel?

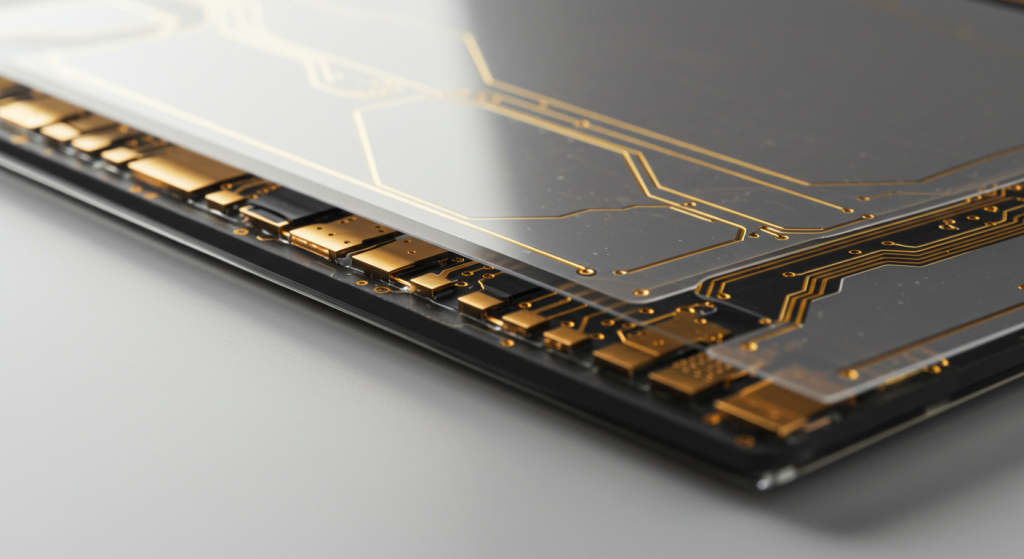

A Conductive film touch panel is another variation of touch, in which the touch is read and processed by a Teflon-like or plastic-like touch-sensitive film laminated over a rigid substrate. Such panels also operate mostly on capacitive or resistive touch systems based on the kind of application and the requirements of performance demanded. They utilize materials in different forms, like Indium Tin Oxide (ITO) and Nano-silver mesh, to give a unique blend of their optical clarity, touch sensing, and conductivity with electrical activities.

Touch Panel Technology: Working of Conductive Film Touch Panels

Such panels essentially operate a touch sensor layer, which is laminated to a flexible PET substrate with transparent conductive film, i.e., as used in touch sensors. As it flows through the surface, connected to the surface capacitive sensing unit or the resistive network senses the change of the electrical properties at the contact point through the capacitive sensing layer or the resistive network. The reading of this signal is done with a touch controller IC, which interprets the signal as an intelligible input to the device.

Important Factors Include:

- Ion conductive support (ITO or conductive polymer)

- Substrate (flexible PET or glass)

- Anti-scratch protective coating

- IC (controller) of signal processing

Material-TOC: ITO and as an Alternative

Whereas there remain touch panels with ITO film, touching one still being a more common occurrence, it is clear that the industry is also evolving with new generation solutions, in the form of:

- Nano-silver mesh is more flexible and practically less resistive

- Graphene films - Rushed to fame through their excellent quality of transparency and conductivity

- Conductive polymers-Specifically, low cost and can happily be assembled upon bendable materials

All these have been tailored to offer enhanced EMI shielding, response time, and panel durability, especially in flexible display panels.

Benefits of the Conductive Film Touch Panels

1. Sensitivity and Accuracy in Good Touch

It is capable of identifying multi-touch gestures that are very swift and quite precise.

2. Slim, Portable Design

Such panels are flexible and can theoretically pinch similar to glass-based touch stacks, yet they are ready to be put on wearables and foldable displays.

3. Attractive and Invisible

The panels can be made practically invisible on top of displays through the use of materials like ITO and Nano-coatings.

4. Durability /Abrasion Resistance

It is also an anti-glare and scratch-resistant coating that adds lifespan and sturdiness in the factory environment.

5. EMI Shielding

Applicable to delicate medical as well as aerospace electronics.

Industry Uses of Conductive Film Touch Panel

- Touch Panels-Industrial

Industrial touch panel has significance in that factories and automation environment are carrying out their activities via effective machine control in the human-machine interface (HMI) panels.

- Medical Devices with Touch Screens

The film types touch screens enable the medical devices to be readily sterilized and in low-profile units.

- In Cars, There are Touch Screens.

The automotive industry is applying capacitive conductive film screens on the interior side of cars because infotainment and control systems are becoming interactive and intuitive.

- Home Control Panels

Transparent conductive film used in the construction of smart thermostats and wall-mounted displays makes it possible in-touch and uninterrupted design.

- Flexible Electronics & Wearable Devices

The increasing prevalence of fitness trackers, smart watches, and health bands suggests that the offering solution is a thin and flexible ITO touch film.

Fabrication Steps

1. Printing Conductive film on PET Mending Film

2. Screen anti-glare / anti-fingerprint.

3. Touch panel lamination of display units

4. FCI-final assembly

The methodology is supposed to maintain optical integrity, give low low-resistance electrode pattern, and give uniformity of panel across units.

New Technology and Trends

It is an age of rapid and novel developments in the industry:

- Enhancements of the capacitive sensing layer to render a more sensitive layer

- Grapheme-based transparent coatings that are more cost-effective and much better at performing

- Recycling is located in the eco-friendly design of the film substrate

- Smart factories and robotics HMI innovation

- Public-accessible kiosks, outdoor, using highly sensitive panels of conductive film

The Appropriate Selection of Conductive Film Touch Display

When deciding on a selective conductive film touch panel, there are even factors that shall be taken into consideration. These variables are the use of a touch panel of choice; it can be an industrial, medical, automotive, or consumer. This is in addition to such aspects as UV exposure, wetness, or mechanical usage. Select a capacitive or a resistive touch technology based on sensitivity and precision needs. Customization, including panel shape, size, and touch points, is essential too. Consider how the panel is to be built in- LCDs, OLEDs, or standalone. In an illustrative instance, a low-cost conductive film screen may be optimally selected to operate under home appliances, and high review human-machine interface (HMI) panels are more useful in the automation industry. Before you select a panel, consider:

- The application type- industrial, medical, automotive, consumer

- Environmental effects -Environmental aspects

- Moisture, UV, or wear and tear

- Touch technology -Capacitive vs. resistive

- Customization needs -Touch points, size, shape

- Integration options -where they may be in LCDs, OLEDs, or in self-modules

We may employ cheap conductive film displays on a home machine, but we may need a good-quality HMI screen in industrial automation.

Conclusion

A conductive film touch panel is in the form of conductive film, and it is not a component alone, but the center of a new era of interaction. Whether driving a wearable health device, medical diagnostic unit, or an intelligent home hub, these panels ensure such technology has a promise, i.e., transparent touch. This is because the adoption of new materials like ITO, flexible substrate, and thin-film electrodes does not make the touchscreen more intuitive; rather, it is about how humans can interface with machines instead. Is your next evolution causing you to consider high-performance touch interfaces? Service, products, and bespoke solutions. Browse WANTY Technologies.

Related Topics

Capacitive Touch Integrated Touchscreen: 2025 Technology

Aug-25-2025

Capacitive Touch Screen POS Terminal – Next-Gen Solutions

Aug-25-2025

Capacitive Touch HMI Interface | Durable & Ergonomic Control

Aug-24-2025

Capacitive Panel OEM Manufacturers – Custom Touchscreen Solutions

Aug-24-2025

Get a Free Quote

✔ 16 Years Manufacture Service ★★★★★

✔ 3 Technical Experts And 52+ Project Engineers Will Assiste You

✔ Wanty Employs Over 52 Engineers, Many Of Whom Come From Leading Tft Lcd Module Companies Such As Tianma And Boe-Varitronix. Each Core Team Member Brings 15 Years Of Industry Experience.

✔ If you would like more information about our products and services, please contact us. Whether you need a standard solution or a customized one, we are here to meet your needs.

✔ Please complete the form below, and the selected location will contact you promptly. Thank you for visiting, and have a great day!