Capacitive Touchscreen Durability: How Rugged Displays Survive?

News

Aug-23-2025

What Does it Take to Create Long-Lasting Touch Panels?

In a digital age, where increased digital engagement is the driving force behind business, touchscreen durability can no longer be a secondary consideration- it is a first-order design consideration. Whether on a smartphone, an automated teller machine, industrial equipment, or even on an outdoor kiosk, capacitive touchscreens are expected to withstand harsh treatment, be responsive, clear, and also look good. This in-depth guide is about the technical and material aspects that contribute to the capacitive touchscreen durability, and also how durability is a big critical factor in consumer satisfaction, operational uptime, and long-term cost savings.

Capacitive Touchscreen Sturdiness: Why Durability is Important?

The durability of a capacitive touchscreen revolves around its first outer covering, which is tempered glass. The majority of capacitive panels use hardened glass of between 6 to 7 on the Mohs scale. This surface hardness provides good protection against reflection, scuffs, daily scratches, and abrasions. These fancy items tend to be made of chemically toughened glass, such as Gorilla Glass, to provide extra protection as well as durability. Such incorporated materials can support and endure the frequent taps and swipes, together with accidental falls, without affecting the sensitivity or construction of a touchscreen.

Projected Capacitive Technology (PCAP)

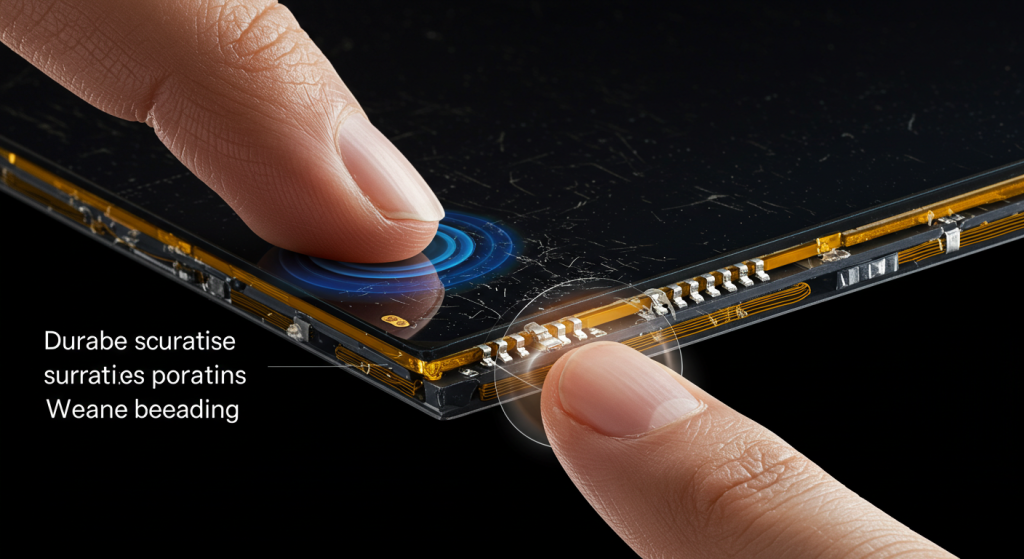

Projected capacitive technology deploys the use of a conductive layer grid sandwiched between glass or plastic sheets. This stability in the performance depends on the integrity of this sensor layer. One quality of PCAP panels is that it has high accuracy of touch and multiple-touch functions that are unlikely to wear down over time. This stability is crucial to places that require constant usage- shopping malls, hospitals, factories, among others. The stability of the sensor layer also forms a significant part of reducing calibration spread and keeping precise input recognition.

Durable Build and Multi-Protective Layers

Multi-layer constructions are a part of durable capacitive touchscreens, which make them stronger. These can be laminated layers, anti-shatter films, and optical bonding to enhance structural strength and better visibility. A rugged design makes the device durable to withstand the effects of mechanical shock, high-pressure touches, and even direct impacts, which qualifies it as military-grade and industrial-grade.

Optical Bonding to Increase Protection

Optical bonding is a process used in manufacturing, which means the touchscreen layer is directly connected to the LCD module and bonded with transparent adhesive. This removes air gaps and gives several advantages: better touch responsiveness, improved readability in sunlight, and most significantly of all, an increase in durability. These laminated layers stop the moisture penetration, lessen the internal condensation, and reduce the risk of delamination. Based on our portfolio of optical bonding products, our products ensure enhanced levels of protection for mission-critical products.

Environmental Resistance ( IP65, IP67 and IP68 Ratings )

IP (Ingress Protection) ratings are used to measure resistance to dust and water of a touchscreen device. Capacitive touch screens deployed in rough environments are frequently rated to IP65, IP67, or IP68. The screens can withstand conditions where they are fully submerged in water/immersed, or in dusty environments with zero performance impairment. As an example, a capacitive touchscreen with an IP67 rating allows 30 minutes of exposure to water, something like 1 meter deep, hence suited to marine, automotive, or fieldwork solution deployment.

Long-Lasting, Natural UV and Chemical Resistance

Capacitive screen, when used under direct sunlight or when a environment is corrosive environment, would require special coating and materials to avoid wear and tear. UV-cure coatings are optically clear and will not yellow, and resist cleaning chemicals, solvents, and industrial fluids using chemically resistant overlays. Such features are especially important in devices used in healthcare or lab settings, which are hygienic and durable concerning operations.

Anti-Glare and Anti-Scratch Coating

Modern capacitive screens usually feature nano-structured or oleophobic coating that helps to increase scratch-resistance and minimize glare. These make the touchscreen to be more easy to clean and able to act under bright light, and also prevent micro-abrasions that would be brought about by styluses, gloves, or any other contaminant. Such additions lengthen the life of a touchscreen in terms of use and appearance, particularly in high-use environments.

Touchscreens by Military-Grade and Industrial-Grade Touchscreens

Military and industrial touch screens have to be incredibly resistant to drops, shocks, and even temperature. Capacitive touchscreens of military grade are designed to operate in adverse conditions (desert, arctic areas, high humidity areas, and so on). We have a rugged touchscreen catalog whose models are designed to meet the MIL-STD-810 and other acceptance standards.

Typical Applications of Long-Lasting Capacitive Screens

- Retail POS Systems: Need a high level of responsiveness and time contention, and must always maintain the same level.

- Medical Devices: Require accuracy, cleanliness, and chemical resistance.

- Industrial Machinery: Work under dusty, wet, and extreme-conditions temperature.

- Outdoor Terminals: Need to be resistant to rain, UV rays, and vandalism.

- Military Equipment: Impact, vibration, and harsh environment-friendly.

What is the Best Way to Test Capacitive Touchscreen Life Spans?

Durability tests are:

- Scratch Testing (Mohs hardness instruments)

- Impact Testing (IK rating drop tests)

- Vibration and Shock Testing (testing a simulated transportation of goods)

- Environmental Testing (UV exposure, salt fog, humidity chamber)

- Life Cycle Testing ( millions of touch cycles)

Such tests are to be done following manufacturers like ASTM, ISO, and IEC.

Ways to Maximize the Service Lifespan of Your Device's Touchscreen

- Apply screen guards of anti-scratch or tempered glass.

- Employ the use of the correct microfiber cloths and non-abrasive cleaners when wiping screens.

- Direct UV light should not be allowed to shine too long to devices.

- Put devices in an environmentally compliant cabinet.

As a screen used in an industrial capacity, select impact and ingress-rated bonded and coated screens.

Conclusion

With the current world being astute to technology, the wear pattern of capacitive touchscreens is critical in determining performance, safety, and endurance. Retrofitting a high-durability touchscreen is both a viable and economical decision as far as we are concerned, long-term. Stand up to the rough and tumble of industrial use –and to the smooth, businesslike demands of a commercial-grade application- durability is paramount, regardless of the type of design. To find out more about very rugged capacitive touchscreen technology suited to your market, please visit our official industrial, commercial, and outdoor products catalog.

Related Topics

Capacitive Touch Integrated Touchscreen: 2025 Technology

Aug-25-2025

Capacitive Touch Screen POS Terminal – Next-Gen Solutions

Aug-25-2025

Capacitive Touch HMI Interface | Durable & Ergonomic Control

Aug-24-2025

Capacitive Panel OEM Manufacturers – Custom Touchscreen Solutions

Aug-24-2025

Get a Free Quote

✔ 16 Years Manufacture Service ★★★★★

✔ 3 Technical Experts And 52+ Project Engineers Will Assiste You

✔ Wanty Employs Over 52 Engineers, Many Of Whom Come From Leading Tft Lcd Module Companies Such As Tianma And Boe-Varitronix. Each Core Team Member Brings 15 Years Of Industry Experience.

✔ If you would like more information about our products and services, please contact us. Whether you need a standard solution or a customized one, we are here to meet your needs.

✔ Please complete the form below, and the selected location will contact you promptly. Thank you for visiting, and have a great day!