Projected Capacitive Touchscreen Suppliers – Top OEM Manufacturers

News

Aug-23-2025

The Guide to Locate the Most Suitable Supplier

In today’s highly interactive digital environment, projected capacitive touchscreens (also known as PCAP) have emerged as the gold standard for modern human-machine interfaces (HMI). These Surface-type screens are sleek, durable, and multi-touch enabled, now being found everywhere, in kiosks and self-service machines (bank ATMs and ticket machines), medical systems, smart-home devices, industrial automation, and outdoor uses. No great touch interface with whom there is no trusted supplier. This paper will serve as your detailed guide in the quest for searching for the global identifying Projected capacitive touchscreen suppliers and will offer tips, technical recommendations, and a supplier selection guide.

What is a Projected Capacitive Touchscreen?

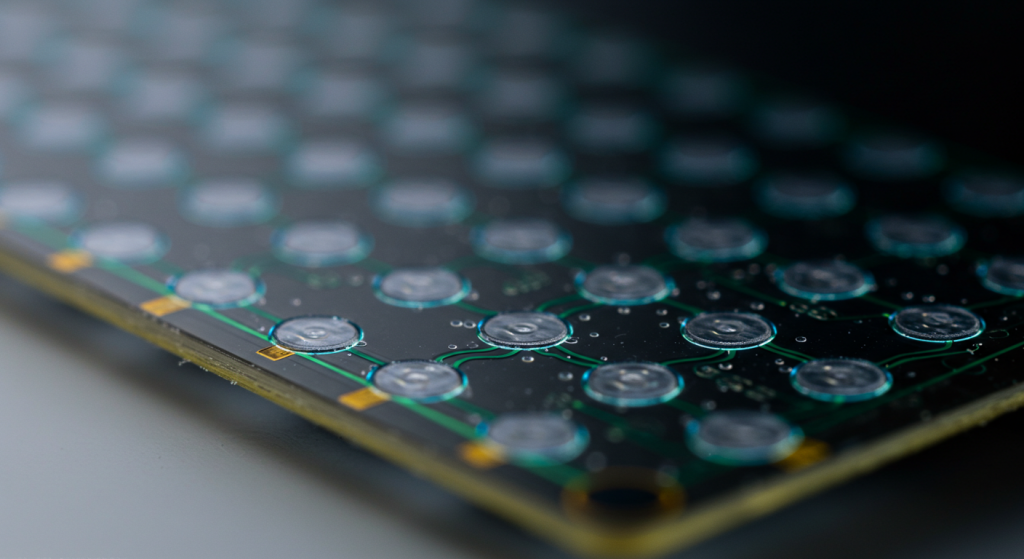

Projected capacitive (PCAP) technology uses a grid of electrodes embedded in a touch sensor to detect the location of touches with incredible precision. Instead, PCAP panels can be made to have multi-touch and multi-point touch capabilities, and weather resistance, wear resistance, and water-resistant functions in addition to being more responsive, unlike resistive. These touch interfaces are so innovative and responsive that more demand will be needed for their use in respective industries, with PCAP being the version used by default.

Technical Highlights PCAP Technology Technically

To make informed decisions when buying these panels, we will consider some of the technical requirements leading to high-quality PCAP panels:

- PCAP Sensors: These rely on a transparent conductive film (TCF) such as indium tin oxide (ITO) layered with glass or PET to detect touch accurately.

- Optical Bonding: This will further enhance the visibility and stability of a display since optical bonding links the touchscreen and LCD together, so the internal reflection is limited.

- Touch Controller IC: Carries a huge weight in terms of performance, which includes signal processing, noise filtering, and touch response.

- Anti-Glare & EMI Shielding: Enhancements like anti-glare coatings and electromagnetic interference (EMI) shielding improve readability and usability in harsh environments.

- Multi-Touch Technology: Allows control using gestures, pinch to zoom, and touches with multiple points that offer more entertaining and usable interfaces.

Significant Uses of PCAP Touchscreen

Projected capacitive touchscreens are very versatile. This kind of use case is a favorite:

- Industrial Automation: Reliable in extreme environments and glove-friendly, as well as gesture sensitive.

- Medical Equipment: Such as the surgical gloves, sterilized and made sterilizable and precise, which makes it subject to the much-needed essential controls.

- Retail & POS Systems: Multi-touch screens that aid customer interaction through stylish screens.

- IoT Devices and Smart Homes: They are used in IoT Devices and smart appliances.

- Military & Aerospace: Rugged is a high shock and thermal tolerance.

Choosing Proper Suppliers of the Projected Capacitive Touchscreen

Selecting the correct source would involve much more than price; it involves finding the correct vendor who will meet your technical needs, customization, and volumes. It has some critical points to be taken into consideration:

1. Technical and Creative Skills

The top vendors involve the latest research and development, as well as present better solutions, and include:

Pc App Gesture Panels

- Glove and water compatibility

- Injection of dependency firmware

- Low form factors

2. Customization Capabilities

Not every project has Off-the-shelf solutions. Look out for suppliers:

- Exact adjustable touch drop receptors

- Variable mounting possibilities

- Optical bonding

- Software and an IC control device, highly customized

3. Industry & Quality Management Certifications

- Ensure that your supplier meets such standards as:

- Certification ISO 9001

- CE / FCC certified

- RoHS standards and Reach standards

4. Volume Flexibility

Your supplier, regardless of your need in small-scale prototype requirements or large production runs, must be able to supply:

- Low MOQ (Minimum Order Quantity)

- Better production lines that are easy to scale up

- Help with fast prototyping

5. Geography/ Supply Chain Strength

Choose suppliers who can offer global logistics, having manufacturing plants in:

- Shenzhen (China-based touch panel factories)

- Europe (EU-certified providers)

- US Exporters

The Advantages of OEM Touch Panel Suppliers

Partnering with an OEM (Original Equipment Manufacturer) touch panel supplier offers a wide range of strategic advantages, especially for businesses seeking tailored solutions and long-term scalability in their touchscreen-based products. These are the greatest of these advantages, and one can find them listed below:

- Effective Supply Chain: OEM vendors almost always have total control of the supply process, such as raw materials and production of final systems, and fewer vendors also means that it is easier to manage the logistics process and product inventory.

- Direct to the Custom Access: The ability to look to the actual manufacturer can give an unprecedented amount of customization and potential needs in size, resolution, touch sensitivity, type of coating, and can include even custom integration of the controller, to give this perfect fit to meet your technical specifications in detail throughout the project.

- Cost-Efficient: OEM collaborations offer cheaper prices due to the fact that one can take advantage of inexpensive offers not only on individual and bulk requests but also in the long run due to the absence of intermediaries and other third-party sellers, etc.

- Design Flexibility: OEMs would typically be flexible design-wise, hence allowing it to vary or alter the existing features in the middle of a project without incurring many breakages or even cost escalation.

- Intellectual Property (IP) Protection: OEM agreements often include clauses for IP security, which is essential when developing proprietary interfaces or custom user experiences that require confidentiality.

Fine-Lines & Novelty in PCAP Technology

The new trends in the industry entailed new components, which were:

• Capacitive Touch, Haptics: Touch-sensing that threatens superior UX.

• Transparent Conductive Polymers: Can be used in place of the ITO coatings on displays that are more flexible.

• Noise Immunity Panels: An essential in both the medical and industrial environment.

• Hybrid Touch Screens: The capabilities of both capacitive and resistive features are combined into an application that does not need high volumes of production.

• Capacitive Touch (Stylus Support): in design, engineering tasks.

Industrially Uses

The adoption of projected capacitive (PCAP) touchscreens has expanded rapidly across a diverse range of industries, thanks to their high durability, multi-touch functionality, and seamless glass surfaces that enhance user experience in both commercial and industrial environments. The greatest areas where PCAP technology has been used in the daily operations of the following sectors are as follows:

Medical and Healthcare: Corrective touch sensitivity, compatibility with gloves, and capability to be sterilized without clean-up processes employed by hospitals, laboratories, and other medical facilities in a diagnostic or monitoring device, among other things, enable them to keep their operations safe and sound in their clinical settings.

Retail and Hospitality: PCAP-based self-checkout terminals, interactive displays, and digital menu tools are gaining considerable momentum among businesses wishing to automate their interaction with the customer, and desire to have a more modern, user-friendly interface.

Banking and Finance: Capacitive touchscreens can find use in banking institutions such as smart banking machines, ATM to offer easy, secure transactions and instant data services to their respective customers.

Who is Your Dream Supplier?

When it comes to sourcing several hundred of your own designed modules or millions of display devices, your projected capacitive touchscreen suppliers can make or break your project. Pay attention to innovation, personalisation, and after-sales for the users. Do not settle for one-size-fits-all.

Wanty is the most innovative PCAP touchscreen manufacturers that possess quality control-intensive display technology and have the potential to export products to every state of the world. We invite you to get to know our broad product line and discover the path to how we can drive your next touch-enabled invention.

Conclusion

In today’s fast-evolving digital landscape, selecting the right projected capacitive touchscreen supplier is critical for achieving high-performance, durability, and seamless user experience. By partnering with reputable manufacturers who offer technical support, quality assurance, and industry certifications, you ensure that your project meets both functional and commercial success. Always prioritize innovation, transparency, and proven expertise when choosing your capacitive touchscreen partner.

Related Topics

Capacitive Touch Integrated Touchscreen: 2025 Technology

Aug-25-2025

Capacitive Touch Screen POS Terminal – Next-Gen Solutions

Aug-25-2025

Capacitive Touch HMI Interface | Durable & Ergonomic Control

Aug-24-2025

Capacitive Panel OEM Manufacturers – Custom Touchscreen Solutions

Aug-24-2025

Get a Free Quote

✔ 16 Years Manufacture Service ★★★★★

✔ 3 Technical Experts And 52+ Project Engineers Will Assiste You

✔ Wanty Employs Over 52 Engineers, Many Of Whom Come From Leading Tft Lcd Module Companies Such As Tianma And Boe-Varitronix. Each Core Team Member Brings 15 Years Of Industry Experience.

✔ If you would like more information about our products and services, please contact us. Whether you need a standard solution or a customized one, we are here to meet your needs.

✔ Please complete the form below, and the selected location will contact you promptly. Thank you for visiting, and have a great day!