Touch Display Optical Bonding: Enhance Clarity & Durability

News

Aug-20-2025

Touch Display Optical Bonding: Next-Generation High-Performance Screens

In the digital age, clarity on a screen, finger sensitivity, and outdoor readability are greatly needed. Touch display optical bonding is taking its place right there in harsh industrial applications, in the hospital and medical world, and in premium consumer products, redefining the performance quality of screens used there.

What is Touch Display Optical Bonding?

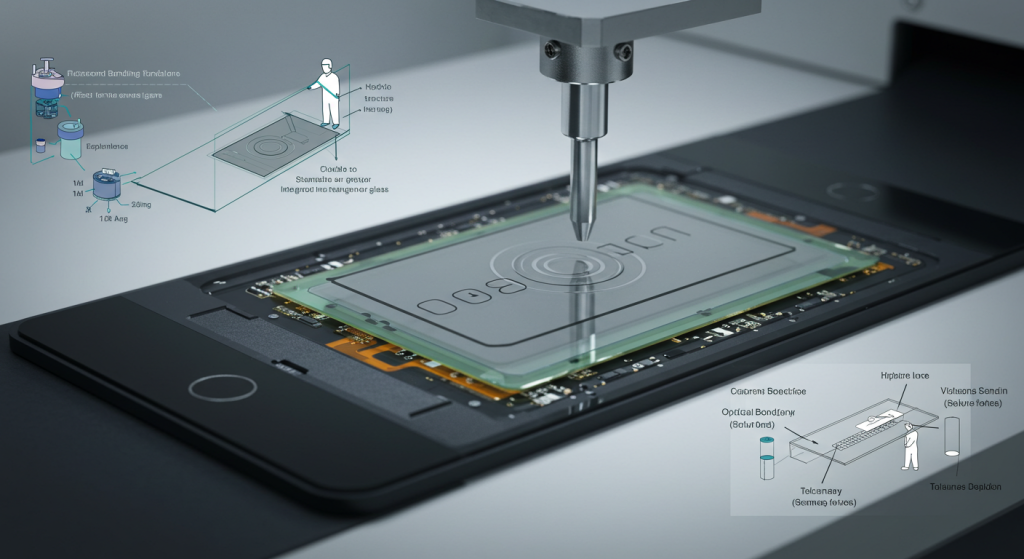

- Touch display optical bonding is a fabrication procedure in which the touch display is bonded to the LCD using a layer of optical adhesive substance to remove the air space. This layer of bonding material occupies the gap between the LCD and the touch panel or cover glass, making the bonding stronger, with better contrast and readability.

- As opposed to the air gap bonding, optical bonding attenuates internal reflections and prohibits moisture entry or dust entry. The technology is particularly needed in challenging conditions where it is essential to have good screens and screen reliability.

Types of Optical Bonding in Touch Screens

There are two bonding techniques mainly:

- Dry Optical Bonding: Lamination is done with solid optically clear adhesive (OCA) films.

- Wet Optical Bonding: It uses liquid optically clear adhesives (LOCA), which fill the gap, then cures under UV light or heat.

All these approaches are advantageous. An example is projected capacitive touch optical bonding that performs very well with both dry and wet optical bonding techniques. Explore the benefits and applications of this cutting-edge display technology.

The Major Advantages of Optical Bonding on the Touch Screen TVs

1. Increased Legibility in Strong Light Settings

Optical bonding eliminates light reflection due to the air gap to a great extent. This gives rise to an anti-reflective optical bond screen, which is ideal for sunlight-readable touch screens.

2. Improved Durability

The bonded screens are more shock and vibration-resistant as the air gap has been eliminated. Optical bonding solutions are used today on rugged touchscreen displays in both military and marine applications, and rugged industrial equipment.

3. Increased Touch Accuracy

The touch sensor can capture input more precisely with a tighter bond. This improves projected capacitive optical bonding technology, and the screen is more attentive and sensitive.

4. Condensation, Dust Prevention

There is no air gap, so in a humid or dusty environment, dust particles and/or moisture are not able to settle between the displays.

5. Added Contrast and Clarity

As a result of the removal of internal reflections, the contrast ratio is increased, enhancing color improvements and viewing.

Some Optical Bonding Uses and Applications

- Industrial

Touch displays, industrial optical bonding displays are found frequently at outdoor kiosks, factory automation, and control panels. Such screens are durable, survive the extremes of nature, and have a long lifespan.

- Medical

Unclean surfaces and poor visibility of diagnostic and surgical products can pose problems, but optical bonding displays make them hygienic, visible, and responsive to touch. It is used to meet the compliance regulations by using medical-grade adhesives.

- Military & Defense

Optically bonded displays can find application in military tanks, aircraft, and field communication systems, and can be easily read in sunlight and are stress-proof.

- Outdoor & Transportation

Optically bonded displays visible outdoors are found in public transport stations, money machines, automobiles, and vehicle dashboards, with the best visibility displayed even when there is direct sunlight.

Touch Screens Custom Optical Bonding Solutions

Optical bonding technology has the great benefit of customization. Manufacturers are in a position to offer:

- Thickness of custom cover glasses

- Anti-glare/anti-reflective coating

- Bonding of high-brightness display,

- Calibration of touch interface (resistive/ capacitive)

- Improvement of the backlight to be seen outdoors when using the touch screen

The touchscreens could be customized to fit all purposes with transparent bonding resin and sophisticated display lamination processes.

Optical Bonding Technicalities

- Adhesive Bonding Layer: A one-of-a-kind component to provide optical clarity, UV stability, and elasticity.

- Bonded Display Assembly: Adheres LCD, a touch panel, and a protective glass together into one, rigid component.

- Optical Interface Bonding technique: Good bond/thermal resistance.

- Increases Light Transmission: enhancing optical clarity and reducing light scattering level.

Long-Term Performance and Reliability

Better durability, touch screen bonding leads to a product that can resist:

- Expansion and contraction in heat

- Conversion of electrical energy into heat

- Genesis and lasers

- Impact and shock

- Excessive UV irradiation

The outcome is a low-maintenance and long-lasting display that can be used in mission-critical applications.

New Trends and Development

1. TFT displays with ultra-narrow bezels, optical bonding

2. Intelligent bonding of curved touch panels

3. Minor scratches stem from optical adhesives, which are self-healing.

4. The connection to industrial monitoring with the help of IoT devices

All of this is leading to even more predictable and reactive display solutions.

Conclusion

Touch display optical bonding is increasingly becoming a necessity in a world where visual clarity, durability, and responsiveness matter as much as it does. Whether it be next-gen medical equipment or outdoor kiosks, the choice of optical bonding display technology delivers a seamless, high-performance user experience. This innovation has ever changed the future of human-machine interaction, with LCD screen optical bonding to rugged touch displays. When it comes to future-proofing your display solutions, you should certainly move towards optical bonding. Want a personalized solution? Check out WANTY Touch Technology to enjoy state-of-the-art displays with your specific needs in mind.

Related Topics

Capacitive Touch Integrated Touchscreen: 2025 Technology

Aug-25-2025

Capacitive Touch Screen POS Terminal – Next-Gen Solutions

Aug-25-2025

Capacitive Touch HMI Interface | Durable & Ergonomic Control

Aug-24-2025

Capacitive Panel OEM Manufacturers – Custom Touchscreen Solutions

Aug-24-2025

Get a Free Quote

✔ 16 Years Manufacture Service ★★★★★

✔ 3 Technical Experts And 52+ Project Engineers Will Assiste You

✔ Wanty Employs Over 52 Engineers, Many Of Whom Come From Leading Tft Lcd Module Companies Such As Tianma And Boe-Varitronix. Each Core Team Member Brings 15 Years Of Industry Experience.

✔ If you would like more information about our products and services, please contact us. Whether you need a standard solution or a customized one, we are here to meet your needs.

✔ Please complete the form below, and the selected location will contact you promptly. Thank you for visiting, and have a great day!