Touch Screen Conductive Coating: Boost Your Display Tech

News

Aug-17-2025

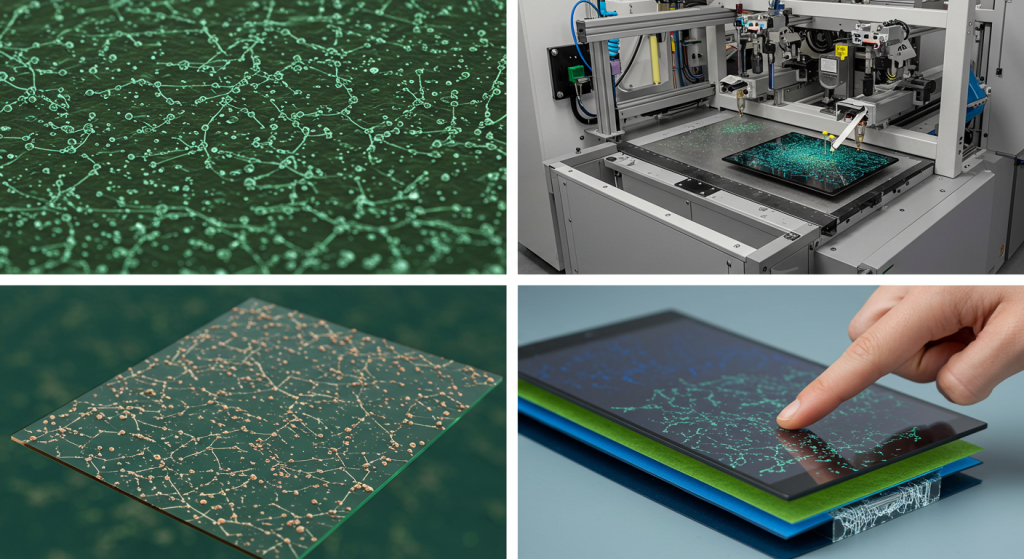

What is a Conductive Coating Touch Screen?

Optical conductive film, an optical conductive film, often shortened to OCF, is a touch screen conductive coating with the property of optical conductivity, that is, it is optically clear, yet conductive to the electrical current. It either has a capacitive or resistive response because it can carry electricity when it makes contact with it. These coatings are required to be able to offer a touch performance that is fast and smooth, and correct.

The covered coating is a conductor with the help of which you will be able to supply the finger signal to the contact area on the screen. It has a variety of display types, and it can be connected to LCD, OLED, and AMOLED. The variation of the types of touchscreen output depends on the nature of the conductive material employed. It most often takes place with the help of the following materials:

- Indium Tin Oxide ITO: this is the most edible, transparent to light, and an excellent conductor.

- Silver Nanowires show very Low conductivity, and Flexibility is very Low

- Graphene-Base Coating: You can see through it, it is very, very fine and strong as Fuck.

- Metal Mesh Coating: The metal mesh coating is applied in the case of big games or other industrial fields of industries.

This is a material that can be worn and is bendable to conductive polymers. These are even better for the development of bending electronics with low expenses. These materials are normally mixed with others in the majority of instances to facilitate improvement in performance as well as to lower the cost.

Techniques and Technologies

A variety of methods have been applied to ensure that a conductive coating of a touch screen is created, and some of them include:

- Thin Film Deposition

- VCP Process

- Screen Print Ink: Conductive Screen Print Ink

- Roll-to-roll coating

- Nano-Coating Uses

- Mark accuracy Laser Marking

All such processes assist in ensuring that the end product that will be produced will be transparent, electrically conductive, and very sensitive.

The Working Principle: Capacitive Vs. Resistant Coatings

It helps to comprehend the huge difference between capacitive and resistive coating to generate preference for the appropriate touch screen technology that is to be utilized in the app.

Capacitive Coating

- Its principle of work is to read the electrostatic body.

- Responsible, sensitive, and spread smoothly and smoothly upon command by touch.

Multi-Touch: Yes

- It is usually glass, and it bears a conductive layer such as ITO.

- It is accompanied by very good clarity and a sparkling screen illusion.

- Ideally suited: Tablets, smartphones, new kiosk, and high-end automobile display.

Hard Coatings

- Touch Mechanism: Finger (or glove-related) or stylus (or glove-related).

- Durability: They are tougher and superior in those areas where things are rough.

- Multi-Touch: no, the touch is only a single one.

- The Material of the Surface: Conducting films in splashy plastic.

- Not Very Bright: The output of the capacitive screens is not very bright.

Wanty can customize the capacitive solutions as per the industry requirements.

Use in Instruments of Practice

The role of conductive coating in the modern world is especially enormous since a wide range of modern technologies is presented based on touch screens. These finishes make them sensitive, accurate, and efficient in their long-term usage, no matter whether they are brainy phones or tablets, or are a component of major applications like industrial touch screens and medical monitors.

- Similarly, wearable electronics would also necessitate very thin, flexible conducting materials that can withstand the curving and other effects of the surrounding environment. The user interface types, such as ATMs, kiosks, can also be provided with scratch-free, anti-smudging clearance that has a matte finish, which in the long run will also provide visibility of the face of user. Military aerospace involves the use of high-performance coatings and conductive films, including ITO, that are sprayed on a surface to produce a high level of performance despite being in a severe space atmosphere.

- New sustainable conductive high-performance touch screen conductive coating. We manufacture our conductive solutions, custom-made solutions related to our technology, and a very high count of systems, both in terms of standard and tailor-made applications and products.

- Encoded in our dielectric layer would be the nicest of the nice materials, like nanosilver wires, graphene, and transparent conducting oxides (TCO) with lovely performance and stability. It will be all innovative, making it brilliant when it comes to invention, achieving the brilliance of sensitivity, optical clarity, and mechanical strength to a greater level so that it becomes smart, silky-smooth, and sturdy in facilitating day-to-day interaction.

The Merits of Touch Screen Conductive Coating are as Follows:

Short, airy, humorous, that is what it is in the first place:

- Full Visibility: What can be seen on the screen is all on the screen and not on the layer.

- The touch of the most touching touch is felt.

- Multi-Touch Support: No problem! The pinching, zooming, and swiping are not an issue!

- Scratch-Resistance: It did not scratch, and it remained clear after a person had been using it on a daily basis.

- Touch as a Fingerprint -resistant: The gadget keeps your screen in a very good state.

This shields the client and the gadget from EMI. The strengths of the Flexibility of Design: It is the possibility to go together with the foldable and curved screens.

New Horizons and New Development

The market is moving at such a fast pace. The current developments are as follows:

- The combination technology consists of Graphene and Nano-Silver Multi-Layer.

- Adaptability of display-screen aids of wearables

- The Self-Healing Coating Materials

- Green Coating Technology

New technologies have led to the movement of the threshold of innovation in a more sustainable and smaller direction.

Conclusion

Fingers, or rather their layer, tend to become real since the magic of touch includes the technology that is presented with the help of a touch screen conductive coating. It can be a phone, a dashboard of a car, or even a display in the surgery, but without the coating, nothing will work in them. The switching of applications and materials will continue to happen, and it will always happen like that. When you are analyzing whether to introduce) a touch interface or whether to upgrade it, the single most important aspect that you must not miss is the invisible portion that makes it work. Visit WANTY.

Related Topics

Capacitive Touch Integrated Touchscreen: 2025 Technology

Aug-25-2025

Capacitive Touch Screen POS Terminal – Next-Gen Solutions

Aug-25-2025

Capacitive Touch HMI Interface | Durable & Ergonomic Control

Aug-24-2025

Capacitive Panel OEM Manufacturers – Custom Touchscreen Solutions

Aug-24-2025

Get a Free Quote

✔ 16 Years Manufacture Service ★★★★★

✔ 3 Technical Experts And 52+ Project Engineers Will Assiste You

✔ Wanty Employs Over 52 Engineers, Many Of Whom Come From Leading Tft Lcd Module Companies Such As Tianma And Boe-Varitronix. Each Core Team Member Brings 15 Years Of Industry Experience.

✔ If you would like more information about our products and services, please contact us. Whether you need a standard solution or a customized one, we are here to meet your needs.

✔ Please complete the form below, and the selected location will contact you promptly. Thank you for visiting, and have a great day!