Capacitive Touch Custom Screen: Tailored Solutions for Your Projects

News

Jun-22-2025

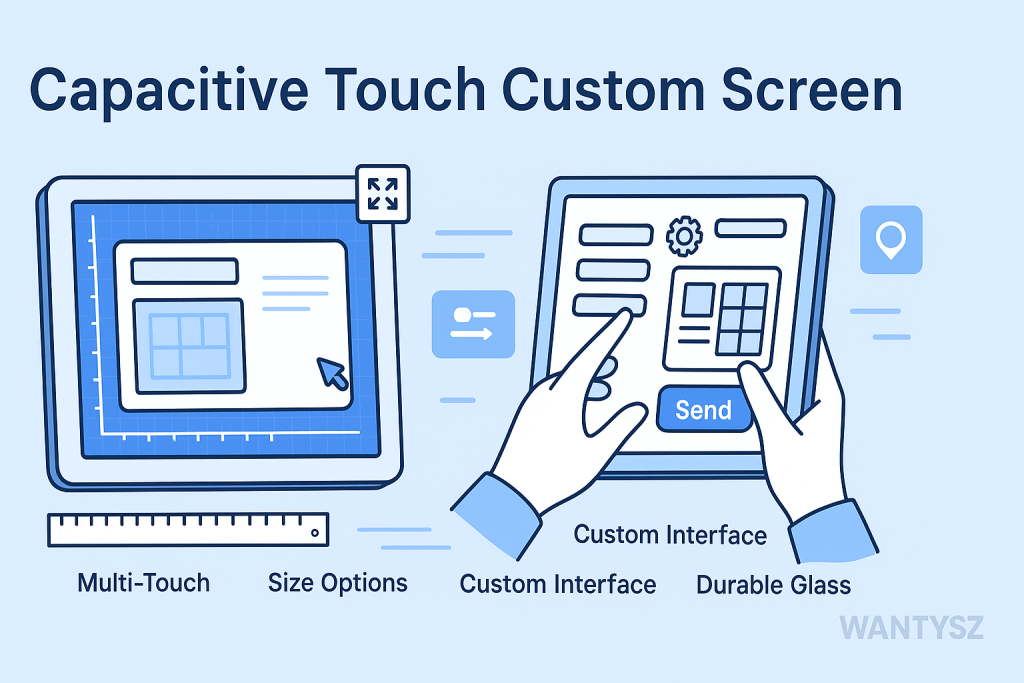

Every project is different, and sometimes a standard touchscreen just won’t cut it. Custom capacitive touch screens give you the flexibility to get exactly what you need—whether that means unique sizes, shapes, or features.

Tailored PCAP screens can be designed to fit your device perfectly, with options for glove support, water resistance, and specialized coatings. These personalized touch displays improve usability and reliability across industries, from medical equipment to industrial controls.

If you’re considering a custom touch solution, it’s important to understand your options and how to work with suppliers who can deliver exactly what your project requires. This guide will help you navigate the process and make smart decisions for your capacitive touch screen needs.

Common Reasons to Customize Touch Screens

Sometimes, standard touchscreens don’t cut it. A capacitive touch custom screen is ideal when your project needs unique design requirements, like a 12-inch curved screen for a medical device or a rugged display for an outdoor kiosk. Customization ensures the screen fits your device’s shape, size, or function, such as a glove-compatible panel for warehouse workers. It also allows features like waterproof coatings for marine equipment. For example, a carmaker might need a tailored PCAP screen to blend seamlessly into a dashboard’s design. Custom screens improve user experience by meeting precise project specs. Customized touch panels solve challenges that off-the-shelf screens can’t, making them essential for innovative OEM projects. Learn more about uses at Capacitive touch screen use cases.

Key Factors in Custom Touch Screen Design

Designing a capacitive touch custom screen involves several important considerations. You must define project specs like size, resolution, and interface options to ensure compatibility with your device. For instance, a retail kiosk might require a 15-inch screen with Full HD resolution for clear visuals. Touch sensitivity needs tuning for specific inputs, such as gloves in a factory setting. The controller IC affects multi-touch performance, which is critical for swiping or zooming gestures. Environmental needs, like waterproof coatings for outdoor use, are also key. Glass type impacts durability, while bezel design ensures a smooth fit. Customized touch panels balance these factors to create an ideal user interface. Collaborating with a capacitive touch screen supplier ensures your design requirements are met for the best user experience.

Selecting the Right Glass and Cover Lens

Choosing the glass type for a capacitive touch custom screen is crucial for durability and user experience. Tempered glass provides strength for high-traffic kiosks, while Gorilla Glass resists scratches, perfect for smartphones. Acrylic offers a lightweight, cost-effective alternative for less demanding applications. For example, a medical monitor might use thick Gorilla Glass for hygiene and durability. Cover lens thickness, ranging from 0.7mm for slim devices to 3mm for rugged ones, influences touch sensitivity. Anti-glare or waterproof coatings enhance visibility and protection, like in an outdoor ATM. The right glass type ensures optical clarity and user interface reliability. Working with a touchscreen supplier helps align design requirements with your project’s needs, creating a robust customized touch panel.

Choosing the Controller IC and Interface

The controller IC is the brain of a capacitive touch custom screen, processing touch inputs. Selecting the right one depends on project specs, like multi-touch needs or glove compatibility. For instance, a retail POS system might use a Synaptics controller IC for fast, accurate taps. Interface options such as USB, I2C, or UART ensure compatibility with devices, like I2C for compact smartwatches or UART for robust industrial panels. Tuning the controller IC for touch sensitivity ensures a smooth user experience, like swiping on a car dashboard. Tailored PCAP screens rely on custom controller ICs to meet design requirements. Partnering with a capacitive touch screen manufacturer ensures the best interface options for your device. For suppliers, see Capacitive touch screen manufacturer.

Defining Size, Shape, and Resolution Requirements

Creating a capacitive touch custom screen begins with defining screen dimensions, shape, and resolution. Sizes vary from 3.5 inches for wearables to 55 inches for kiosks. Shapes can be flat, curved, or flexible, like a curved screen for a car dashboard. Resolution ranges from 720p for small displays to 4K for large touch tables, ensuring optical clarity. For example, a 15-inch retail kiosk screen might need Full HD for sharp menus. These project specs impact touch accuracy and user interface design. Customized touch panels are tailored to fit unique devices, enhancing user experience. Clear design requirements ensure the screen aligns with your project’s needs. For cost estimates, see Capacitive touch screen quote to plan your budget.

Multi-Touch and Gesture Support Options

Multi-touch is a standout feature of capacitive touch custom screens, enabling gestures like pinching or swiping. You can customize touch points, from 2 to 10, to suit your device’s needs. For example, a tablet might require 10-point multi-touch for sketching, while a kiosk needs 2-point for simple swipes. Gesture support enhances user experience, like zooming on a medical monitor’s X-ray image. The controller IC must be tuned for touch sensitivity to handle inputs smoothly. Tailored PCAP screens offer custom gesture profiles for specific tasks, improving user interface usability. A personalized touch display with multi-touch ensures intuitive interaction, ideal for commercial applications across industries, from retail to healthcare.

Environmental and Durability Considerations

Capacitive touch custom screens can be built for harsh conditions. Waterproof coatings protect against rain or spills, perfect for outdoor kiosks. Anti-glare coatings ensure optical clarity in bright sunlight, like in a park ticketing system. Thick glass types resist scratches and impacts, suitable for high-traffic retail environments. For instance, a factory control panel might use a rugged tailored PCAP screen to withstand dust and vibrations. Design requirements like glove compatibility are ideal for cold storage warehouses. Customized touch panels prioritize durability to ensure reliability in industrial environments. These features keep screens functional, enhancing user experience. Collaborating with a touchscreen supplier ensures your project’s environmental needs are met for a lasting user interface.

How Custom Screens Improve User Experience

A capacitive touch custom screen elevates user experience by meeting your device’s exact needs. Tailored screen dimensions fit seamlessly, like a 12-inch screen for a medical monitor. Custom touch sensitivity ensures precise inputs, such as a doctor tapping to adjust settings. Multi-touch enables intuitive gestures, like swiping on a kiosk to browse options. Waterproof or anti-glare coatings improve usability in tough settings, like outdoor ATMs. For example, a custom personalized touch display in a car dashboard delivers clear visuals and fast responses. Tailored PCAP screens create seamless user interfaces, enhancing usability across commercial applications. Custom design requirements ensure your device stands out with a reliable, user-friendly touchscreen module for any project.

Typical Industries That Use Custom Capacitive Touch Screens

Capacitive touch custom screens serve a wide range of industries. Retail relies on personalized touch displays for kiosks, enabling quick checkouts. Healthcare uses glove-compatible screens for medical monitors, ensuring touch accuracy. Automotive dashboards feature curved tailored PCAP screens for navigation controls. Industrial factories need rugged screens for control panels, resisting dust and grease. For instance, a warehouse tablet with a custom screen tracks inventory efficiently. Gaming consoles, smart home devices, and educational tools also use customized touch panels for interactive interfaces. These capacitive touch screen use cases highlight versatility. Explore more at Capacitive touch screen use cases. A capacitive touch screen manufacturer crafts screens to meet design requirements for user experience in diverse commercial applications.

The Customization Process: From Concept to Prototype

Creating a capacitive touch custom screen begins with your idea. You share project specs like screen dimensions and interface options with a capacitive touch screen manufacturer. Engineers design a prototype, such as a 15-inch kiosk screen with glove compatibility. The prototype is tested for touch sensitivity and durability, allowing you to provide feedback. Adjustments to the controller IC or glass type refine the design. Once approved, sample prototypes pave the way for production. For example, a retail chain might test a custom screen for POS systems before ordering 1,000 units. The process ensures customized touch panels meet design requirements. Lead time for prototypes is typically 4–8 weeks. Clear collaboration with your touchscreen supplier delivers a reliable user interface.

Sample Production and Testing

Sample prototypes are essential for perfecting capacitive touch custom screens. Manufacturers produce a small batch, like 5–10 screens, to test design requirements. For instance, a medical device company might evaluate a 12-inch tailored PCAP screen for touch accuracy. Tests verify multi-touch, durability, and interface options like USB. Environmental tests ensure features like waterproof coatings or glove compatibility perform, such as in a factory panel exposed to grease. Feedback refines the controller IC or glass type before mass production. Sample prototypes confirm user experience and optical clarity. Testing takes 1–3 weeks, ensuring production quality. Partnering with a capacitive touch screen supplier guarantees reliable samples. For purchasing guidance, see Buy capacitive touch screen.

MOQ and Lead Times for Custom Orders

MOQ and lead time are critical for capacitive touch custom screen projects. For example, a kiosk project ordering 500 screens might pay $150 each. Lead time is 4–8 weeks for prototypes and 8–12 weeks for production. A tailored PCAP screen for a car dashboard could take 10 weeks. Suppliers like Zytronic offer no MOQ for flexibility. Clear lead time planning ensures custom orders meet deadlines. Discuss MOQ and lead time with your touchscreen supplier to align with project specs.

Working With Manufacturers for Custom Solutions

Collaborating with a capacitive touch screen manufacturer ensures custom capacitive touchscreens meet your vision. Manufacturers like Elo or Touch International provide engineering expertise to refine design requirements. For example, a factory might work on a glove-compatible tailored PCAP screen for control panels. They assist with selecting controller ICs and interface options to optimize touch accuracy. Sample prototypes allow testing user experience before production. Manufacturers offer certifications like ISO 9001 for production quality. Regular communication ensures lead time and MOQ fit your timeline. Strong B2B partnerships deliver customized touch panels for commercial applications.

Requesting a Custom Quote

Obtaining a capacitive touch screen quote for a custom capacitive touchscreen requires detailed project specs. Specify screen dimensions (e.g., 15 inches), resolution (e.g., Full HD), and interface options (e.g., USB). Include MOQ (e.g., 1,000 units) and features like waterproof coatings or glove compatibility. For instance, a retail chain might request a quote for 500 kiosk screens with multi-touch. Ask for lead time, certifications, and unit prices. Suppliers like Faytech typically respond in 3–7 days. A precise touchscreen quote request ensures accurate pricing. Compare quotes from multiple touchscreen suppliers to find the best deal. For guidance, see Capacitive touch screen quote. Clear custom requests secure tailored PCAP screens for your user interface needs.

Integration and Installation Considerations

Integrating a capacitive touch custom screen demands careful planning. Ensure enclosure compatibility with screen dimensions and mounting hardware, such as a VESA mount for a kiosk. For example, a car dashboard screen requires exact bezel integration for a sleek user interface. Secure wiring with shielded cables to prevent interference, especially in industrial environments. Calibrate touch sensitivity for multi-touch or glove compatibility. Test durability in real conditions, like a dusty warehouse. Proper touch screen installation solutions guarantee reliability. Customized touch panels need tailored interface options for seamless integration.

Troubleshooting and Support for Custom Screens

Troubleshooting capacitive touch custom screens ensures consistent performance. If a screen lags, recalibrate touch sensitivity or clean the glass surface. For instance, a kiosk screen might misread taps due to smudges. Check wiring for loose connections, common in industrial environments. Test controller IC settings for multi-touch issues. Manufacturers like Elo offer 24/7 support to resolve problems, such as updating firmware for a medical monitor. Environmental tests verify waterproof or glove compatibility features. Customized touch panels rely on after-sales support for durability. Request troubleshooting guides from your touchscreen supplier to maintain production quality. Strong support ensures user experience for tailored PCAP screens in commercial applications.

Cost Factors in Custom Capacitive Touch Screens

Capacitive touch custom screen costs range from $100 to $5,000. Screen dimensions influence pricing: 7-inch screens cost $100–$300, while 21-inch ones reach $500–$2,000. Features like glove compatibility or waterproof coatings add $50–$500. MOQ affects unit prices: 100 units cost more than 1,000. Tooling for custom orders adds $1,000–$5,000. For example, a 15-inch kiosk tailored PCAP screen with anti-glare might cost $400. Certifications like ISO 9001 increase expenses. Budget for lead time and sample prototypes to ensure production quality. Compare custom touch display prices with your capacitive touch screen supplier to balance cost and quality.

Case Studies: Successful Custom Screen Projects

Capacitive touch custom screens enable groundbreaking projects. Elo produced 2,000 personalized touch displays for retail kiosks, offering multi-touch for quick ordering. Zytronic supplied 1,000 glove-compatible tailored PCAP screens for warehouse tablets, ensuring durability. Faytech delivered 500 customized touch panels for medical monitors, meeting ISO 13485 standards. Touch International created curved screens for car dashboards, enhancing user experience with touch accuracy. These capacitive touch screen use cases showcase production quality across industries. Custom orders from touchscreen suppliers drive innovation in retail, healthcare, and automotive.

Conclusion

A capacitive touch custom screen offers unmatched versatility for your project. Customized touch panels meet design requirements like unique screen dimensions, glove compatibility, or waterproof features, ensuring a perfect fit for retail kiosks, medical devices, or car dashboards. Tailored PCAP screens enhance user experience with multi-touch and touch accuracy, while durability thrives in industrial environments. Collaborate with a capacitive touch screen manufacturer to create sample prototypes and align with MOQ needs. Plan for lead time and unit prices to balance cost and production quality. For purchasing guidance, explore Buy capacitive touch screen. A personalized touch display elevates your device with a seamless user interface. Contact a Capacitive touch screen manufacturer to launch your custom project!

Related Topics

Capacitive Touch Integrated Touchscreen: 2025 Technology

Aug-25-2025

Capacitive Touch Screen POS Terminal – Next-Gen Solutions

Aug-25-2025

Capacitive Touch HMI Interface | Durable & Ergonomic Control

Aug-24-2025

Capacitive Panel OEM Manufacturers – Custom Touchscreen Solutions

Aug-24-2025

Get a Free Quote

✔ 16 Years Manufacture Service ★★★★★

✔ 3 Technical Experts And 52+ Project Engineers Will Assiste You

✔ Wanty Employs Over 52 Engineers, Many Of Whom Come From Leading Tft Lcd Module Companies Such As Tianma And Boe-Varitronix. Each Core Team Member Brings 15 Years Of Industry Experience.

✔ If you would like more information about our products and services, please contact us. Whether you need a standard solution or a customized one, we are here to meet your needs.

✔ Please complete the form below, and the selected location will contact you promptly. Thank you for visiting, and have a great day!